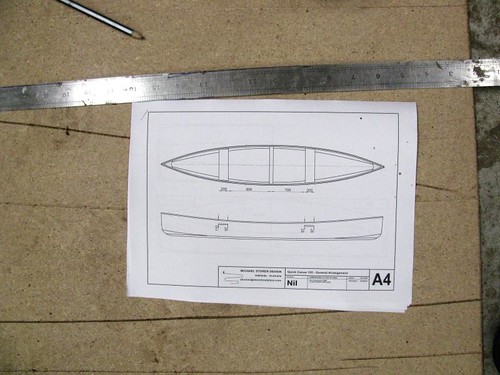

USA precut canoe kit available

I had really hoped I would be able to build the boat in a day.

I ended up being slower than the fastest builders of my canoe – Rick and Clinton1 who managed to build this plywood canoe in 4.5 and 5.5 hours respectively.

It is the first time I have felt disappointed taking a day and a half to build a boat including all the details. The biggest hold up was I was using a water based exterior glue and in the wintry weather (need I mention the deluges of rain we had) it just wouldn’t dry so I wasn’t able to shape things or trim them off as quickly as if it was the summer. In the end I should have used epoxy which would have taken the same amount of time except for glass taping the hull together.

All the bits and tools before …

I was doing it on the the cheap, so tried to source cheap plywood. The local exterior ply was so bad I decided to use the cheapest marine ply which had really nice faces and was only $12 more expensive per sheet – this is in Australia – it will be much cheaper to build the boat in North America or Queensland for that matter where ply prices are more competitive.

I used polyester resin to tape the boat up because I know it would cure in a couple of hours rather than overnight, which should and did save me a day. I had the glass taping done within 3.5 hours of starting cutting the panels on Friday morning. Polyester is not the best choice for a boat you want to last for a long time, but it cures in an hour or so instead of overnight like the higher quality epoxy resin.

In the end the big defeat was that I got the boat together but could not sand, round or trim any of the timberwork because of the slow glue. It was like watching grass grow in such damp conditions.

Anyway … here is the flickr slideshow